The perfect choice of one-stop service for diversification of architecture.

Digah armored steel door vendor for balcony

1. The design of Digah steel doors for sale is imaginatively conceived. It is designed to fit different interior decorations by the designers who aim to elevate the quality of living through this creation.

2. This product is less likely to generate harmful electromagnetic rays which may cause diseases such as headache, diabetes, or even cancers.

3. The product features efficient dehydrating. The top and down structure is arranged reasonably to allow thermal circulation evenly to go through each piece of food on the trays.

4. Guangzhou House Empire Construction&Furnishing Co.,Ltd has established the first-class corporate culture management and brand image in steel door industry.

OEM/ODM | Acceptable |

MOQ | 1 Set |

Package | Plastic Foam+Paper Package+Strong Carton |

Delivery Time | 15-30 days after sales confirmation |

Port | Guangzhou,Shenzhen etc. |

Payment | T/T,Western Union,Money Gram,etc. |

Features | Security, waterproof, bulletproof, soundproof,fir proof |

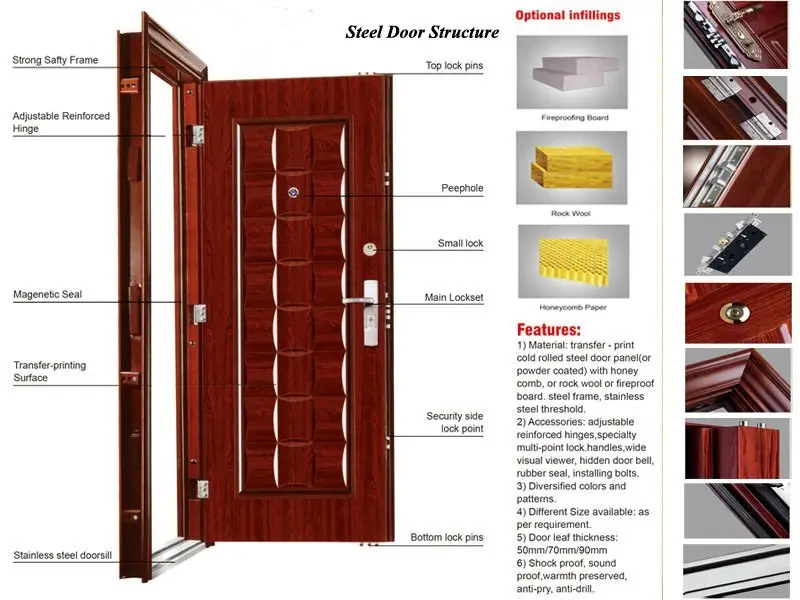

As a high-grade entry door, armored door is also an upgraded product of ordinary anti-theft door.

1. It adopts high quality steel plate, processed through advanced composite technology and wood veneer compression into mould,its surface is natural wood grain. The color is lifelike, natural, clear texture, strong and stereo.

2. Its door body has strong impact resistance,with the function of anti-theft and anti prying.

3. A vast of different colors of wood and patterns according to the requirements of users are available with personalized design,which is a perfect interpretation of quality life.

Company Features

1. Guangzhou House Empire Construction&Furnishing Co.,Ltd enjoys high comments among customers at home and abroad.

2. Our factory is repleted with advanced imported production facilities. These facilities are produced under cutting-edge technologies, which finally contributes to increasing our average annual production capacity.

3. As a socially responsible business, we continuously improve and track environmental performance, and improve the understanding and guidance of the environment for all employees. Our company bear social responsibilities. There are a few charities that are close to our hearts and each year our team engages in fundraising activities to raise money.

The ACCURL® Hydraulic press, engineered with great care for details, is a high quality machine tool. The studies made on the framework flections have allowed us to design a product that reacts in the most appropriate and responsive way to the mechanical solicitations, therefore guaranteeing a stable structure, thus a higher precision in deep drawing.

ACCURL® design & manufactures High-speed C-Frames Hydraulic Presses from 250 to 2500 kN for high-rate, deep-drawing processes in several industrial application areas for Aluminum & Stainless Steel parts (i.e. automotive, houseware, cookware, job type works and others).

Customized for your Production:

- In addition our Presses are produced on the basis of Accurl china standard or, alternatevely, on technical specifications agreed with customers.

- User-friendly control

Versatility:

- Configuration on demand

Precision:

- Force from 600 to 300.000 kN

- Monolithic and composite structures

- Customizable Table dimensions

- Customizable Stroke

- Safety Standards: CAT3 e CAT4

- Mold Change systems available

- Software: Siemens touch screen

Safety:

ACCURL® has a strict policy for the choice of its components, on the basis of an extensive experience acquired over decades. All components are certified in accordance with European standards and their main sources are Germany, USA, Holland, Italy and Switzerland. All structural parts are calculated by the finite element method and only high quality steel S275 and S355 JR namely J2 (+ N) is used.

Reliability:

ACCURL® All structural plates used are made of steel alloys ( i.e. S355 or higher), are certified and verified for chemical analysis and mechanical testing. The assembled elements are welded together and normalized, i.a.w. UNI-EN10025 regulations. The structures are designed to improve load distribution and lower associated tensions, so to minimize distortions.

The design of the presses adopts a welded & robust steel structure ensuring a compact and stable machine that reduces to the minimum its deformations during the working cycles. Commercial components are selected only from the major supplier existing on the market and each press is incorporating all required safety elements to satisfy Cat 3 and Cat 4 Safety Standards. By asimple selection on the machine control panel it is possible to perform several important tasks, like dies-settings for the Mobile Table and Drawing Cushion, manual cycling for pre-production trials and Standard Production using the Semi-Automatic Cycling.

• Electric welding of high precision

• Usage of high-tech boring machines for extreme precision parts

ACCURL® chooses the best products to guarantee long-lasting and high-techmachines.

ACCURL® selects the best components.

APPLICATIONS:

• Graphic color CNC

•The composite series has been designed for applications in which structural rigidity and lexibility in terms of production are the particular rerogatives required. Machines with several actions from the top or bottom or pecial solutions enable complex shapes and large dimensions to be achieved in a number of different industries, such as:

• domestic appliances

• car and vehicle bodies

• structural elements

• stainless steel door

• cooker tops Laser beam safety photocells

• Silent and reliable internal gear pump

• High precision optical lines

• Electrical panel with high quality components

• Start&Stop system

ACCURL® machines comply with the strictest EU regulations with referenceto safety. The devices installed guarantee thorough safety of the operatorwithout reducing the pace of work.

• The most advanced laser systems

• Safety PLCs able to manage and monitor the action of the proportional valves

• Visible dual beam linked to the upper tool: should it be is interrupted, it blocks the movement of the Deep drawing

• Easy adjustment by means of a grading scale

• Constant monitoring of parameters related to safe

91.8% Response Rate

91.8% Response Rate

91.8% Response Rate