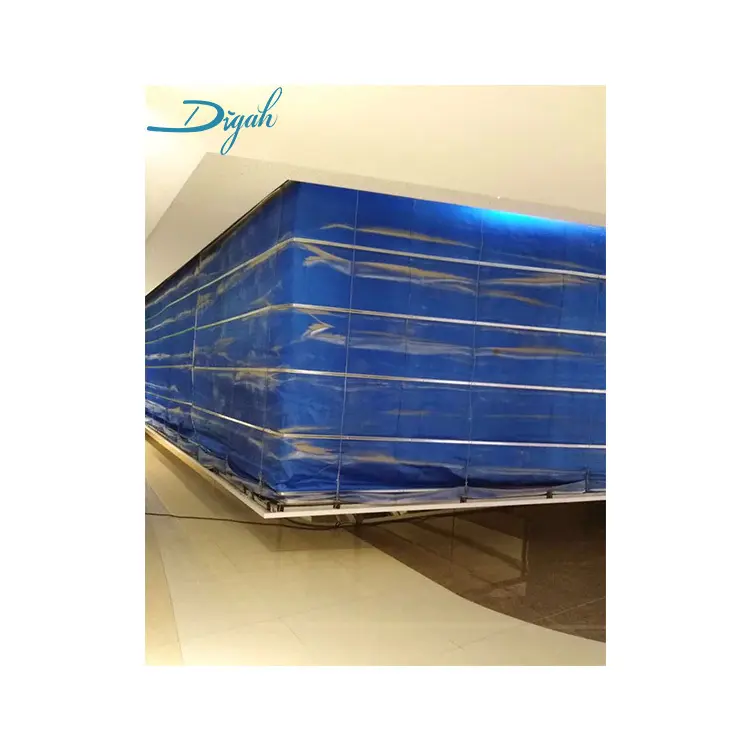

The perfect choice of one-stop service for diversification of architecture.

Fix Loose Bridge Saddle Screw

Fix loose bridge saddle screw

Loctite might help. You pour a little bit on the thread (having undone it a bit 1st so that when you do the screw up again, the loctite is pulled into the thread) and is prevents things vibrating loose. People use it on cars and models a lot.Loctite HomepageThread locking sectionIt allows you to undo the thread if you need to though. You can feel that it's locked up, then as you undo the nut/screw etc you feel it ping as it lets go (normally quite easily)I would advise trying a snmall amount at first - just enough to get the thread a bit wet. You do not what it locked to thight that you can not adjust anything !You can buy it in most DIY shops or motor spares shops

— — — — — —

How can I fix this problem?

When it happened to me I managed to get the post to hold by stuffing the hole tight with match sticks with the head torn off, then replacing the screw. I also wrapped a layer of writing paper around the screw thread. Unfortunately, it was not a permanent solution but it held for a few months.

— — — — — —

Unclear answer. How do I unscrew if I don't know the screw position?

If you can not find the slot, then get a screw extractor which has a barb type bit which will grab the metal of the screw and remove it. Otherwise, righty tighty, lefty loosy.

— — — — — —

If you have a very tight screw and you apply heat to it, will it make it tighter or more loose?

If you have a very tight screw and you apply heat to it, will it make it tighter or more loose?It depends.If it's a normal metal screw in a normal tapped hole, then it is tight because it's been torqued to some value. The action of the inclined planes of the thread convert that applied torque into stretch of the screw. The axial force that goes along with that causes friction, which prevents the screw from unscrewing, so the screw continues to apply the axial force that holds the parts in place. With this normal application of a screw, if you could magically heat just the screw, then the screw would expand and the increase in length would reduce the axial force. The radius of the screw would also increase, but for a normal screw in a normal tapped hole, there is radial clearance, so there would not be any binding due to the increase in radius. The net result is that the screw would get looser. HOWEVER.It is not easy to warm up just the screw. It is firmly pressed against the metal it is screwed into. Suppose you have a steel screw screwed into a tapped hole in a block of aluminum. Whatever heat you apply will end up heating up the aluminum as well as the steel screw. Aluminum expands more than steel when heated, so heating them up will cause the screw to get tighter. Effectively the aluminum will expand in the axial direction more than the screw, so it will stretch the screw even further. This is despite the fact that the hole also gets larger in diameter. The net result is that the screw would get tighter. You might be able to get the screw to loosen by cooling the joint instead.If the steel screw were screwed into a block of titanium, then you'd have to reverse the above. Steel expands more than titanium when heated. Of course, there are things like nylon screws. That will expand faster than metal and that will tend to loosen the axial load assuming you've sized the screw and hole correctly.The above was all for a normal screw in a normal hole. If for some reason the screw is oversize or the hole is undersized, then most of the torque will go into grinding the threads against each other. There won't be much axial force. Now, if you heat the screw, when it expands it will increase the radial forces and that will make the screw tighter. Cooling would make it looser. But this is for a non-standard case where you've really buggered up the threads. Think 10-32 screw forced into an 8-32 hole. I'm not sure that is even possible to do, mind you.Later: There have been a lot of comments about 'stuck" screws. Let me emphasize what I already said. The above was all for a normal screw in a normal hole.I'm talking about a screw that is tight, not one that is stuck. It could be tight because someone torqued it to a high level. That does not mean it is stuck. I'm not talking about a screw that is corroded and stuck. I'm not talking about a screw that is misthreaded. I'm not talking about a screw that has been forced into a hole that is too small. I'm only talking about a screw that is tightened a lot. The question asks about 'tighter or looser." It doesn't say anything about 'stuck. " I realize that many people who have read this question have interpreted 'tight" to mean 'stuck." When I read the question, I did not read it that way.If you have a very tight screw and you apply heat to it, will it make it tighter or more loose?.